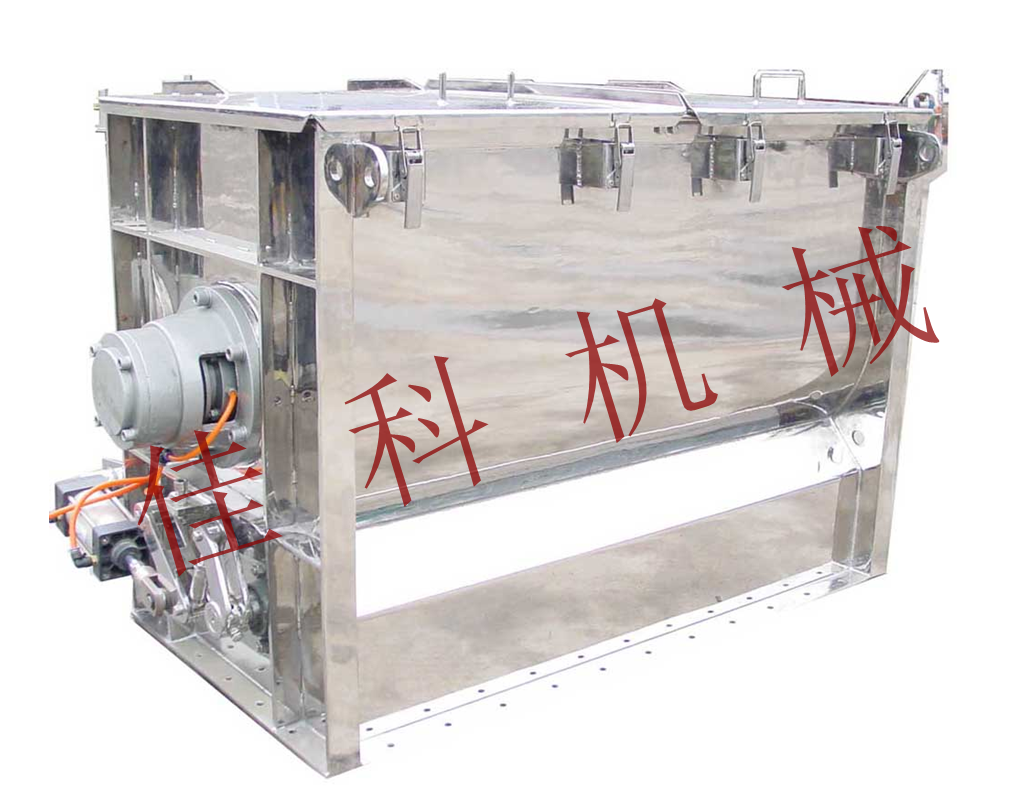

Model No.︰WLDH-100L

Brand Name︰JiaKe

Country of Origin︰-

Unit Price︰CNY ¥ 18000 / pc

Minimum Order︰1 pc

The main purpose

WLDH ribbon mixer is a new type of high-efficiency, high-precision mixing equipment, widely used in pharmaceutical, food, chemical, and other industries, can be used for the mixing of powder and powder, a small amount of liquid powder mixing, powder and Particle mixing and other processes.

Structural features

The WLDH ribbon mixer consists of a mixing chamber, an agitator, and a drive unit. A U-shaped tubular chamber is equipped with a double-layered contra-rotating ribbon coiled stirrer shaft. The outer spiral belt is driven by power, and the coiled form cooperates with the rotation direction. The material is pushed from both ends of the U-shaped silo to the central zone, and the inner spiral belt pushes the material from the middle to both ends to form convection mixing.

The WLDH ribbon mixer has a discharge opening at the bottom of the cylinder. The screw structure of the outer spiral belt drives the material inside the cylinder wall to the central discharge outlet in accordance with the rotation direction of the spindle to ensure that there is no dead angle in the discharge of the material in the cylinder.

Performance introduction:

1. Flexible selection scheme

The horizontal groove mixer can be customized with carbon steel, manganese steel, 304 stainless steel, 316L stainless steel, 321 stainless steel and other materials, and different materials can also be used in combination;

Dividing the equipment when selecting materials: contact with materials and non-material contact;

The interior of the mixer can also be targeted to add functional coatings or protective layers such as anti-corrosion, anti-adhesion, insulation, abrasion resistance, etc.;

Stainless steel surface treatment is divided into sandblasting, wire drawing, polishing, and mirror treatment, and can be applied to different parts of the application.

2. Reliable drive configuration

The mixer is configured with different capacities, different powers, and different output rotational speed driving devices according to the nature of the material, the starting mode, and the stirring mode.

The choices of drive motors include: ordinary motors, anti-riot motors, variable-frequency motors, high-efficiency energy-saving motors, high-protection-grade motors, and motors under different voltages;

Common reducer: R, K, F series gear reducer, cycloid reducer, general-purpose gear reducer, planetary gear reducer;

Common connection methods: direct connection, pulley connection, hydraulic coupler connection.

3. Efficient stirring device

The mixer can be configured with different stirrers according to different material properties;

Conventional material mixing points: different powders are mixed with each other, batches of the same material are mixed, powders are mixed with a small amount of liquids, liquids are added to the slurry, the slurry is thickened or diluted, particles and powder are mixed, and the particles are mixed Material and pellets mixed, agglomerate material crushing, cooling or heating mixed.

Horizontal Mixer modified stirrer can be divided into: inside and outside the spiral, blade spiral ribbon, internal and external broken ribbon, razor and so on.

4 excellent discharge device

The horizontal spiral ribbon mixer is equipped with an aerodynamic curved flap valve. When the valve is closed, the curved surface flap of the valve completely conforms to the arc surface of the cylinder. During the stirring process, there is no unnecessary dead angle of the blend, making the blended material more uniform.

The valve drive can be divided into manual, pneumatic, electric three.

Valves for reference include powder spherical valves, roller valves, plum blossom misalignment valves, powder butterfly valves, and rotary feed valves.

5. Various ways of opening

Different types of openings can be set on the cylinder cover of the mixer to meet the different working conditions. According to the role of the opening can be set manholes, cleaning doors, feeding port, exhaust port,

Dusting mouth, etc., the opening form has a flange-type standard opening, quick opening with cover door.

The mixer can be set to a full-open lid type, which is convenient for cleaning the inside of the equipment.

6. Powerful auxiliary components

Mixer can be installed with a variety of components, commonly used coil steam jacket, honeycomb pressure jacket, circulating medium jacket, online sampling valve, high speed flying knife, magnetic separator, temperature detection, weighing system, Dust purification and other components.

The jacket of the mixer uses jackets of different types according to different heat source media. It can be heated and cooled to a maximum temperature of 250 degrees Celsius.

When adding a small amount of liquid, the spray spray device needs to be configured, which is more conducive to the uniform dispersion and mixing of the liquid in the main material.

The liquid spray system consists of three basic components: a pressure source, a liquid reservoir, and a spray head.

7. Closed shaft seal

Mixer commonly used three kinds of sealing modes: packing seals, modular air seals, mechanical seals;

Spindle seals for pellets, powders, micron powders, liquids, and slurries.

WLDH Series Ribbon Mixer Selection Method

1. Determine the volume of material to be mixed in each batch, ranging from 0.1 to 20 cubic meters. Select the appropriate equipment.

2. Select the material used to make the equipment. The material is divided into parts that are in contact with the material and parts that are not in contact with the material. The other parts of the equipment are kept in the original material.

(Materials are based on the nature of the material, working conditions, health level and other factors, conventional carbon steel, 304/316L/321 stainless steel)

(Determine surface treatment requirements according to requirements after material selection)

3, according to the material's specific gravity, fluidity and other properties, as well as the starting standard to determine the configuration of the drive capability.

(starting standard points: heavy load start, no load start)

4, according to the actual process conditions, increase the auxiliary functional components, such as spray, heating / cooling, and so on.

5, the opening requirements of the design equipment, such as feeding mouth, cleaning mouth, exhaust hole and so on.

6, select the material mode and drive mode, manual, pneumatic, electric.

Important note: The selection of the equipment is an important part. We should provide detailed material information and process arrangements as far as possible so that our company's professionals can provide you with quality technical services.

Payment Terms︰ TT